Sports and leisure under air cushions

Jean-Claude Brehm, project leader at SEELE, the company responsible for design and construction of the roof, explains that Ethylene Tetrafluoroethylene is a polymer developed originally for aerospace. "It has been known in the construction industry for about 15 years and is now quite commonly used in Germany and the English-speaking countries, but is only now starting to become popular in France." The ETFE membranes are between 50 and 300 µm thick and form pneumatic cushions set in aluminium frames. The cushions are inflated with air at low pressure to give an insulating layer and withstand the effects of wind load.

The main advantage of this technique is doubtless its cost which is three times lower than traditional glass roofs. But ETFE is largely a different, complementary material that is not really in direct competition with glass. For some projects where the thermal requirement is not a discriminant criterion, the ETFE air cushion technique has the advantage of adapting to almost any organic form imaginable. Its lightness, durability, solar radiation and UV transparency and its anti-adhesive properties which enable the envelope to self clean by the action of rain all make its use worthwhile in projects involving sports facilities, horticultural greenhouses or unheated spaces such as train stations or shopping malls.

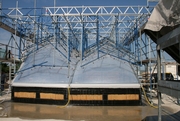

Modules 42 m long

For the Vitam’parc project located 11 km from Geneva, the air cushions for the translucent roof of the Aquatic Centre were formed using three membranes forming two overlaid air chambers. 66 cushions of this kind were aligned along the width of the building, marrying the timber and steel frame of the building in the shape of a marine mammal. With dimensions totally different from those of the construction materials generally used in roofing… Rising to a height of 16 metres, the total length of the largest cushions is no less than 42 metres! They are kept at a pressure of 300 Pa by a continuous dry air flow maintained by two pumping stations which compensate for seal integrity defects, while eliminating the risk of condensation.

Given the lack of existing standards and reference documentation for these inflatable structures, the CSTB has developed a proving system for the technique in partnership with the inspection agency SOCOTEC. Aurélie Godin, the engineer responsible for the ATEx, reports that the test protocols were established by analogy with those designed for traditional glass roofs. ”Water, air and wind resistance tests were carried out on a life size model. An impact test representing a man falling from his own height also enabled us to evaluate the strength and safety of the membranes.” Five large files of reports, observations and descriptions of the technique were the final outcome of this collaboration on the project - designed by the Spanish architects L35. An experience that could be of particular benefit to all the parties by establishing standard conditions or an initial Technical Assessment.