Evaluation of heat pumps: combination of virtual and real

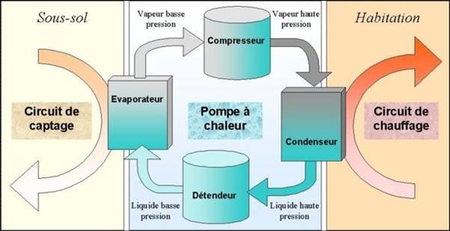

It is a genuine field of geothermal boreholes, arranged in a double U and at a depth of 20 metres. This equipment can extract energy from the ground or inject energy into the ground. This borehole field is connected to CSTB's semi-virtual laboratory, the PEPSY (Platform for the Evaluation of Performances of dynamic SYstems). These two platforms can be used to evaluate the behaviour and performances of the global system of a geothermal heat pump. Geothermal boreholes can be connected to a virtual heat pump and a virtual building, or they can be coupled to a real heat pump itself connected to the hydraulic network of a virtual building. In this case, part of the system to be tested (heat pump, storage tank, pumps, regulation, etc.) is actually installed in the laboratory, while the building or the house (with its distribution and heat emissions, occupants, equipment, climate and geothermal exchangers) is simulated numericallly. The boundary between the “real” and “virtual” parts can be freely determined as a function of the product to be tested … (See diagram).

Adaptability at the service of a complete system

This adaptability is the main advantage of this experimental platform; the behaviour and performances of the heat pump are evaluated based on a complete system combining geothermal boreholes, heat pumps and buildings. Unlike conventional tests, performances are annual or seasonal rather than nominal (for example for heating, the COP (Coefficient of Performance) is an annual or seasonal COP and is not a nominal COP). The robustness of product control is also tested at the same time, which is not the case at the moment with standard tests. Therefore data on the heat source, emission, heat pump and auxiliaries are included with data characterising the inertia of the global system, building regulation, etc. The result is an analysis and a global performance calculation including all relevant parameters i.e. equipment, climate, typology, building use, etc. It offers a genuine advantage for manufacturers who wish to optimise their industrial products or improve prototypes; only a short period and a few tests are necessary to optimise a particular heat pump for a set of climates, buildings or different soil types, while guaranteeing results close to reality.

Saving time and money

A priceless advantage … Because it is well known that genuine monitoring is normally essential to evaluate the performances of a geothermal heat pump installation. This “real” monitoring usually needs one or even several years including at least a heating season and a cooling season, thus respecting the natural rhythm of the seasons. This monitoring is not only long but is extremely expensive on a large scale. CSTB has developed a unique methodology that goes beyond these constraints. It uses a 12-day test sequence defined based on climatic data (for example reference weather files). A numeric calculation automatically determines the appropriate test sequence. In this test (in which each day of the test corresponds in a certain manner to the average day of one month), the heat pump outlet temperatures (at the evaporator and at the condenser side) and the corresponding flows are measured and sent to the virtual environment at each time step of the test (namely every 5 seconds). In return, the simulated environment calculates the conditions of fluid to be controlled at the inlet of the heat pump (realised using charge and discharge loops). Temperature sensors, for example to determine the temperature in the zone or the outside temperature, are replaced by variable resistance boxes exactly reproducing the temperatures of the virtual system, so that the heat pump and the regulation act as they would in a real building.

Peter Riederer, CSTB geothermal laboratory, concludes: “12 days instead of 365 is obviously attractive! We could even reduce this time further for some of the systems. In any case, we are working on it …”

Very low temperature

The different projects under way at CSTB only apply to so-called "very low temperature" geothermal heating, in other words a temperature at which a heat pump is necessary. The use of the term "geothermal" is slightly abusive for part of the geothermal exchangers such as horizontal collectors or spiral heat exchangers); heat stored in the ground at this level is mostly due to solar energy or runoff of rainwater rather than originating from the depths of the earth's crust.

Several test platforms available

- Conventional thermal machine platforms: tests of heat pumps, cooling equipment

- “Systems” platforms: virtual laboratory for testing and optimisation of heat pumps and systems under realistic, non-nominal dynamic conditions

- Geothermal probe platforms: test and analysis of geothermal boreholes (BRGM and CSTB platforms)

- Multi-site platforms: use of others in networks – BRGM and CSTB multi-site platform