Recycled waste, preserved environments

In a context of sustainable development and rarefaction of raw materials, recycling of waste is a strategic national challenge. Waste is an important flow of energy and material: biomass 500 million tonnes; buildings and public works 350 MT; sediments 50 MT; household waste and packaging 30 MT; used vehicles and tires 2 MT; electrical and electronic equipment waste 1.7 MT, etc.

Faced with this challenge, CSTB has oriented its design and research work based on two themes: manage waste and make good use of it. In other words, give them a second life, by creating secondary raw materials (MPS in French). They can then enter a new life cycle and are used to manufacture materials and products.

Fly ash and used tires

In terms of research, CSTB has been working in partnership with the ADEME and the DGUHC (Direction Générale de l'Urbanisme, de l'Habitat et de la Construction) (General Directorate of Town Planning, Habitat and Construction) in the framework of the EEDEMS GIS, and has developed a framework of good waste reuse practices in the construction sector called "MPS methodology". It is addressed to manufacturers such as communities, holders of waste who would like to define ways of reusing it, construction product manufacturers who would like to incorporate secondary raw materials in their products.

This methodology specifically describes the preliminary phase before the product is put on the market (feasibility study)… "The "opportunity – vigilance" pair inherent to recycling was the starting point for our study to define this framework of good practices, explains Emmanuel Jayr, CSTB specialist in the waste and building themes. Reuse is an environmental opportunity to reduce the quantity of waste to be eliminated and especially to prevent consumption of new raw materials, some of which are not renewable and are becoming rare. Furthermore, these recycling practices must be implemented taking account of technical, economic and environmental aspects, and also health and social aspects to be sure that the manufactured product is suitable for use and respects the environment and health, to put the industry on a firm footing to assure that it is sustainable."

For example in the concrete industry, some “historic” waste is already being used as completely independent raw materials. For example this is the case for fly ash derived from the combustion of coal in thermal power stations, particularly because they improve or they add new properties to concretes in which they are incorporated.

Pre/Post partnerships

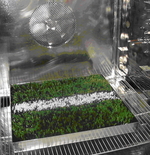

Research also applies to the reuse of used tires, which may for example be recycled as pellets, incorporated in acoustic undercoats or in lightweight concrete or used as a floor covering for sport rooms or gymkhana rings. At the request of ALIAPUR (an association composed of tire manufacturers and created within the framework of the Manufacturer’s Broadened Responsibility), CSTB has participated in a tire pellet characterization study for the development of synthetic turf. CSTB experts have also been asked to provide help in recycling residues from the heat treatment of waste water treatment plant sludge. "These ashes are mineral materials with properties making them suitable for use in the concrete industry", says Emmanuel Jayr. We can recommend the most relevant reuse application, depending on the characteristics of the material."

Consultancy is the other service offered by CSTB to manufacturers who would like to use or reuse secondary raw materials. "Once the properties of the waste have been characterized, we can suggest ways of reusing it, targeting products into which it could be incorporated: insulation, structural material, etc., states Emmanuel Jayr. We can then assist the manufacturer in the development of a product incorporating the secondary raw material: formulation, technical performances, environmental and health characterizations, economic approach, etc."

The manufacturers involved either stock waste on the input side, or manufacture products on the output side. "We always need to form this pre / post partnership to make sure the industry will be sustainable, and to bring all players into contact with each other, adds the expert. Note that considering the rarefaction of raw materials, the demand is not only from manufacturers. More and more design and engineering offices and owners are asking us to given them lists of products containing recycled waste"

This output side pressure is becoming increasingly strong and is related to the emergence of environmental concerns, and should encourage manufacturers to incorporate more secondary raw materials in their products.