Wind tests before facing the wind

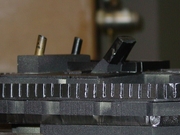

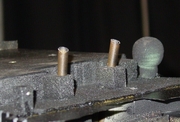

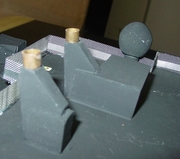

The air in CSTB's Nantes's centre sometimes smells of the wide open sea. It is true that the Atlantic is not far away … and STX France Cruise SA shipyards where some of the largest liners in the world are built are not more than a few tens of kilometres away. "STX France Cruise SA has appointed us to carry out services on the aerodynamics of boats under construction on a number of occasions, says Marc Dufresne, CSTB engineer. We do this by making high density polyurethane foam models that we put into the wind tunnel to study behaviour facing the wind. Sometimes, we work in partnership with our colleagues at the Eiffel aerodynamic laboratory in Paris, to carry out some tests."

Comfort facing the wind

Three types of test are done on luxury liners built in Saint-Nazaire. The first is to test comfort under wind as experienced by passengers enjoying the facilities provided on the upper decks. Liner speeds frequently exceed 20 knots (about 40 km/h), and at this speed a head wind of only about 10 or 15 km/h will make pools, playgrounds and other solariums near the front unusable if protection screens are not correctly sized. "Verifications are made using a hot wire probe that we move around to different points on the ship model when it is placed in the wind tunnel, says Marc Dufresne. Once measurements have been acquired, we suggest means of improvement if drafts are faster than acceptable limits for comfort. These means can apply to the configuration, height and arrangement of wind break screens".

Plumes and wind action

Ship owners also like to predict the behaviour of plumes emitted from chimneys (engines, incinerators, kitchens, laundries, etc.). There is no question that fumes generate "auto-pollution" that is unpleasant for passengers and the crew. Once again, when a problem is detected during the tests, CSTB initiates an iterative process of discussions with its customer to find a solution: increasing the velocity of plumes at their release from chimneys, increased elevation of flues, etc. "The third aspect of our know-how relates to the analysis of forces applied on superstructures by facing and crosswise wind and their impact on manoeuvrability of the ship, continues Marc Dufresne. We can thus determine a coefficient of penetration in air, more or less equivalent to the Cx calculated for cars." A study that can lead to ship redesign work in extreme cases.

A good understanding of the problem

"We have worked with CSTB many times on aerodynamic problems, particularly dealing with comfort on the decks near the prow of a liner. Our needs were quickly understood and exchanges were very successful. As a result of this cooperation, we changed the size of the wind break screen as it had been originally designed. All we need to do now is to check if reality complies with forecasts when the ship is floated!", says Loïc Morand, Aker Yards hydrodynamic engineer.